If you are in business for any length of time you are likely to encounter every organization’s nightmare: Receiving parts or products with defects.

Defective parts can significantly delay your schedule and create manufacturing inefficiencies. And when these defects make it all the way out the field and into your customer’s hands, there’s even more at stake. Not only do you have to deal with the monetary cost of the returned product, but also your company’s reputational cost.Defects are a fact of manufacturing life (unfortunately), and they occasionally happen even with the best of suppliers. But what sets great suppliers apart from average ones is the way they address instances of defectiveness with their customers and the measures they have (or put) in place to correct these issues.

It’s not enough for a supplier to simply replace a defective component. The supplier must provide confidence that they have processes in place to mitigate defects and efficiently handle defects when they occur.

In this post we’ll discuss some of the corrective-action processes suppliers should have in place to ensure quality products and a strong relationship with your organization.

Corrective Action Process

The best suppliers have robust, in-depth corrective-action processes that dictate exactly how they respond to defects and quality issues to ensure their customers are not negatively impacted moving forward.

The process to develop the corrective action is as follows:

1. Isolate the problem

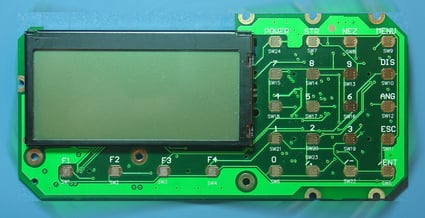

This is the first step after you have identified that your product does not meet your specification. For an LCD display it is typically along the line of an abnormal backlight, LCD color, missing pixels, contamination or touch panel response issue.

For contamination or missing pixels the defect is generally related internal to the LCD display itself. But for the other defect parts, often the problem can be upstream of the display and related to the hardware that is driving the display. Prior to contacting your supplier we recommend a quick A/B test where the suspected defective display is tested on a different “known good” assembly and a “known good” display is used in the “issue” assembly. This way you can more clearly identify whether the problem rests on the display side or the assembly side.

2. Failure Analysis

When the defect rate is high enough it will trigger a failure analysis. This failure rate is something that is agreed upon between you and the LCD supplier and could be as low as one defect.

A proper failure analysis determines exactly what the defect is, and what in the process allowed this defect to occur. Often this may involve LCD suppliers’ supply chain if the defect is caused outside of the LCD supplier’s direct manufacturing of the LCD display.

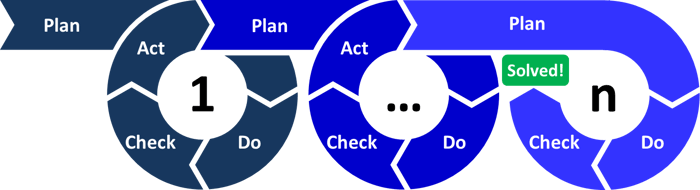

3. Corrective Action

A corrective action is a permanent change in the process such that the defect is no longer able to be re-produced. It’s best practice to not blame people for a defect but instead focus on the process. If the defect is operator error, there is a good chance that the manufacturing process was not created adequately; the work instructions were poorly written, incorrect, or incomplete. Other times it could be a better fixture or better tools, and finally it may come down to operator training around a core skill.

4. Containment

Is the corrective action effective at permanently removing this defect from all future production? Now that the corrective action is permanently in place, each new defective part needs to be evaluated in the same way. If the same defect is still making it through the production line with the same root cause, then the corrective action is not containing the problem and needs to be reevaluated.

Examples of Corrective Action

- Corrective action can take many forms, but there are a few common practices that have been proven to be particularly effective. Here are just a few examples, in context:

- At a high level, sometimes corrective action comes in the form of changes to the company’s documented best practices and procedures. When the defect is the result of human error, corrective action may mean implementing new training processes and skill requirements for personnel. If the issue is mechanical, machinery and equipment upgrades, recalibration, or even replacement could be the corrective action.

- The suppliers who are most effective at implementing corrective action do so in a self-contained, transparent manner that flows throughout the supply chain and the organization. These effective suppliers do a corrective action routinely for any systematic defect as well as for lower than normal internal manufacturing yield rates as well.

Solving the Problem (Before There’s a Problem)

If you’re wondering whether your supplier is designed to effectively handle defect issues and perform corrective action, ask yourself these questions:

- Is my supplier reactive or proactive when an issue arises?

- Do reports of defects send my supplier scrambling to find a quick solution, or is their organization designed from the bottom up to quickly, effectively, and comprehensively solve issues in their supply chain?

- Is my supplier open and honest about their mistakes and the actions they take to correct them, or do they simply apologize quickly and hope I’ll just forget and move on?

- Is my supplier’s philosophy on defective parts the same as mine?

If your supplier doesn't have processes in place to ensure quality products, and/or the answers to these questions leave you wary about your supplier's capabilities, it may be time to make a change. Interested in learning more? You can click here to watch informative videos about LCD displays (and other display-related subjects).

And to find more about LCD specific defects and possible corrective actions, please contact us.