The following design “gotchas” are the ones we most often encounter with our many display integration customers. There are plenty more when it comes to designing displays, but these are the ones we generally help our customers get past on their way to successful product designs. Here we will help you identify and avoid them.

1. Start by understanding the product's purpose. In short, know your market. Essential questions to have clear answers to include:- What information content does the end product need to display? Is it text, images, both, monochrome or color?

- Will it also need LED indicators?

- What type of interface will the end user have, touch panel, e.g. soft keys, or hard fixed function buttons?

- What physical environment will the user be in? Indoors, outdoors, hot cold, humid? This should include both storage and operation.

- How far away will the user be?

- What kind of ambient lighting will it be in?

- Will users touch it, and will it need to be protected?

- Is there a motion component in the use? Are shock or vibration design challenges?

2. Understand the size the display needs to be and how much content you are trying to present. Often the customer’s resolution request is much too high to be usable. This goes back to content and whether the desired content can be adequately displayed on the requested size of display.

Example: I was working with an engineer and his pixel density request was pushing the limits of monochrome technology. The reason? He had a limited required display size and needed to support Han Chinese characters. When the design phase was complete, it was evident that by pushing the display limitations to accomplish this high resolution for a small size, the resulting font size was so small that you had to be a few inches away from the display to read it. This wouldn't have been a workable product solution.

To avoid this, we suggest our customers always mock up a display first. It's quite easy to create the content and print it on paper in the desired display size and resolution before spending months of work and lots of money designing a display.

3. Stick with standard design guidelines when possible. Conservative designs are typically more successful. Although, that’s not always possible, or in the best interest of making your product cutting edge. But anytime you push the limits, you'll likely be increasing cost and possibly reducing reliability.

Also, there's a far greater degree of security in staying with more commonly available technology when possible. The rarer the component, the higher the cost, the longer the lead-time and the more likely it is to experience obsolescence during the product's lifetime.

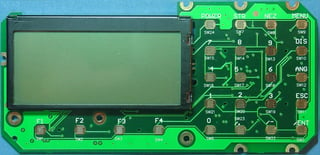

4. Go custom and integrate. Design so the display and end product fit together perfectly. Move components to the most appropriate, logical locations. Often buttons overlay and LED indicators are more efficiently placed on the display itself.

- 5. Eliminate components. By mounting components on the display PCB, you can eliminate sub-PCBs, components, and connectors. Less is more.

Further examples:

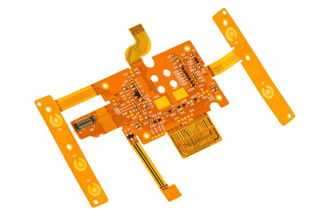

- Integrating all functions into a single, main cable (backlight, LCD, touchable).

- If a board-to-board cable is required from a display, integrate one end into the display with a hot-bar solder connection. It becomes far more reliable by eliminating a connector mating pair for a less complex, lower cost assembly.

6. Shrink it! Make the product only as big as is needed. Anything more, wastes space and increases cost. For example, reduce the connector size, determine the interface you will use and only bring out pins for that option. Only use “no connects” and “grounds” when needed.

7. Don’t forget to drop it! If it's portable, it’ll be dropped. We've all done it, so integrate drop testing in the early stages.

8. Consider your design options effectively. Here’s how: Ask yourself, “If I add this component or feature to the display, will I either sell more of my product or will it sell at a higher price so the profit margin exceeds the difference in expense between the two design options?” Engineering always involves trade-offs. And your market always determines what's going to be attractive to purchasers and users. So know your market, including competitors.

Find out how easy we could integrate with your organization as your new display supplier. Contact us today.