When you’re responsible for purchasing LCD displays for your organization, you’re typically charged with obtaining cost reductions. With that constraint, you’re challenged to find the cheapest displays available.

While that’s an appropriate stance to take, it can also be a very costly one. Cheaper doesn’t always result in a lower system-level and overall product cost, especially over time.

All too often decisions only consider the upfront charge, or initial purchase price of the displays. However, the real price is the complete manufacturing costs required to produce the end product, which also includes production and post-production costs, such as added assembly time, additional integration components, internal defects, and field returns. Not to mention a reduction in performance could impact your overall sales as well.

Instead, seek the greatest value of displays, instead of just the cheapest; this is more globally stated as simply the lowest life of product system-level cost.

To illustrate this concept, let’s look at what happens when you simply examine the backend costs that can affect your bottom line profitability.

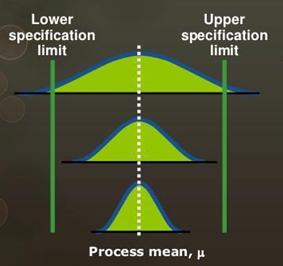

Part-to-Part Variability

To offer a lower-than-market price, a manufacturer has to be able to operationalize this on their end, or simply go out of business. That means they have to employ lower-cost materials, lower-cost suppliers, and simpler internal manufacturing processes. In a steady state environment, these reductions will lead to an increase in part-to-part variation. You will see this variation due to the low-quality materials, the lack of manufacturing process control, and often unapproved product component changes.

This translates into manufacturing challenges at your assembly line, which includes mechanical fit issues and electrical contact and degradation issues. Resulting in slower manufacturing process times and in some cases parts simply won’t fit or work in your assembly. And even worse, some will have shorter product life due to these internal variations.

Lower Overall Performance

For an LCD display, performance aspects are those that affect the use of your device. Conceptually, does the display do what it was designed to do? Applicable aspects are ones such as brightness, contrast, response time, color gamut, viewing angle, etc.

With a “cheap” display, there is a higher chance it will not meet the designed specifications for one or more of these performance aspects.

Additionally, cheap displays may be significantly limited when it comes to environmental conditions. They may not be able to operate or perform as intended in the environmental condition ranges the product was intended to be used in.

Then there’s the danger of shorter product life. Even if these “cheap” displays don’t outright fail, statistically, they will not last as long as their higher-quality counterpart.

Greater Number of Failures

With lower-quality parts, you will have more out-of-the-box failures. This is an increase in manufacturing costs and an increase in QA management overhead costs.

Additionally, lower-quality components have a higher risk of field failure. This is the most expensive of all failures, as the costs of returning and repairing or replacing the device are significantly higher, as are the costs associated with the reputation and brand perception damage stemming from inferior quality.

Less Content on the Display

While this may seem obvious, not all organizations look at this correctly. There is an optimized structure of efficiency for each component. Taking the display for instance, it may include an additional keypad, touch panel, and LED indicators. Removing these components from the display will reduce the LCD display cost for sure. But these components now need to be purchased separately and assembled and managed by you. This particular example typically results in a much higher system-level product cost than having this integrated into the LCD display.

“Cheaper” does not directly translate into the lowest product cost for your company

You know the old saying “you get what you pay for.” That’s certainly true when it comes to purchasing LCD displays. There’s a greater price to be paid for lower quality. Consider the long-term monetary costs, lost productivity, project delays, and even loss of reputation. There is a right level of quality for each and every product and industry and this right level yields the lowest system-level product cost.

Just remember that a lower LCD display price does not always equate to a lower end-product cost.

Need a new supplier that understands your unique display needs and can produce custom displays that address them at the greatest value? Let us help. Contact us.