You’ve been there before: Customer commitments you’ve made have been missed. Your production facility is line-down, effectively bringing it to a complete halt. And all parts are sitting idle waiting for the longest lead-time component — the LCD display — which is now extremely late.

Maybe this is a onetime occurrence, or perhaps it’s systematic, happening much more often than you’re comfortable with.

Either way, it’s time to take action, which means you’re now forced to look for ways to improve lead times or seek other alternatives. Whatever your particular situation, there are options to shorten and/or ensure your lead times with your display supplier(s).Here are the factors that could be negatively affecting your lead time, as well as tips about what to look for in a display supplier to correct these issues.

Capacity

As much as we might like to have a supplier that stands ready and waiting at our beck and call, the hard truth is that your suppliers serve other customers. We can be affected when these other customers have increases in demand, as there are only so many production hours available in a day.

We can also be affected when the entire industry or economy changes. We have different economic conditions from year to year, as well as a common seasonal capacity occurrence due to holidays.

Understanding your supplier’s capacity is critical. Of course you should be worried if you are your suppliers’ only customer; however, a busy supplier at full capacity will not be able to handle any process variation, which means they will be consistently late.

A healthy capacity range for a supplier is about 70%–85%. This means the supplier has enough volume to achieve manufacturing efficiencies, while still having the excess capacity to handle process variation and changes in demand.

Supplier Capability

Each supplier has a unique core competency. When you’re requesting a product that is outside of your suppliers’ core area of focus, there can be manufacturing complications that result in late delivery and missed commitments.

Check out our video on supplier problems here:

Seek out companies that are focused and experienced in building the specific types of parts you actually need, not suppliers who are expert producers of a product or technology you have no interest in procuring.

Volume Compatibility and Prioritization

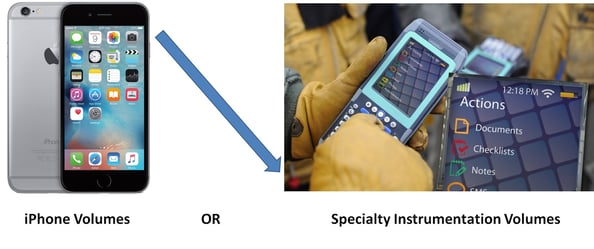

Many suppliers try to be everything to everyone when it comes to the types of clients they serve. They promise to fulfill every type of order ranging from single units to millions of units. This enables them to attract a wider range of customers, but it also makes them less specialized to serve your unique needs; not to mention it can also make you less of a priority.

Every company jumps higher for their larger customers. LCD display suppliers are no different. Know where you stand with your supplier. Ask yourself; are you the typical customer, the largest customer, or are you on the small side? When there is an issue, and your product needs to be expedited over another customer, your supplier evaluates your significance to determine whether you take priority.

Learn about your supply chain at the onset of the relationship, and make sure that you’re well within a comfortable range of your suppliers’ typical customer base.

Safety Stock

LCD display lead times are probably one of the longest lead times on your bill of materials (BOM) — typically 8–12 weeks. If your forecasted demand does not go that far out, or your supplier is consistently missing the delivery dates, implementing a fixed quantity of safety stock is the easiest solution.

This stocked material can be either held at your facility or contractually with your supplier. The downside is the increase in inventory costs and possibility of excess material liabilities, but those downsides typically outweigh the negatives of late deliveries and missed delivery commitments.

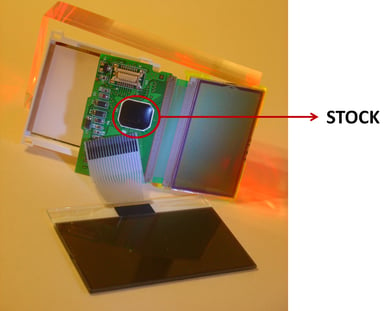

Subcomponent-Level Stocking

An LCD display’s lead time is easy math: Longest lead-time component + manufacturing time + transit = lead time. In situations where this lead time is not manageable, it can make sense to stock only the long lead time subcomponent instead of bearing the costs and liabilities of stocking the entire LCD display. This is especially beneficial when there is a small component with a much longer lead time than the balance of the LCD materials.

Shipping

Shipping methods are a great area of opportunity for improving lead times. For example, some suppliers ship LCD displays from China by sea. (FYI, nearly 100% of all displays are built in China.) This is a more efficient way of shipping, which reduces the overall product costs and results in a lower-cost display.

Shipping by air can also be viewed as a very convenient buffer stock option that can be implemented any time. The difference between ocean and air freight is about 3.5 weeks. So at any time prior to the vessel’s departure, your products’ shipping methods can be changed and transported by air, which is one of the easiest and expedient options available.

Takeaway

Missed delivery commitments are one of the most costly and detrimental problems to have as a company. With just one component missing, an entire assembly line shuts down, dramatically reducing the operational efficiency of the assembly line, diminishing profitability, and missing customer deadlines.

Working with the right supplier for your unique display needs is essential to receiving consistently accurate lead times. Leveraging any or all of these strategies eliminates any regular occurrences of LCD delivery issues and makes you well positioned to handle any unplanned demand from your customers.

Interested in learning more? You can click below to learn about the 5 most common problems with LCD Displays.