You’ve determined that you need a Capacitive touchpanel. Did you know about the different options available? And if so, how do you start figuring out which type will work best for your application?

Here’s a look at what to consider in the decision-making process, and an overview of all the options you have.

Anti-Glare (AG) - By using diffuse films with surface anomalies, reflected light is fragmented and dispersed. This makes the reflected image blurrier, which allows the user to focus more on the intended image instead of the reflected image. Anti-glare films are more visible to the human eye, so should be used when there is minimal reflected light (e.g. indoor environments). Too much anti-glare (or light dispersion) can negatively affect the overall clarity of the display.

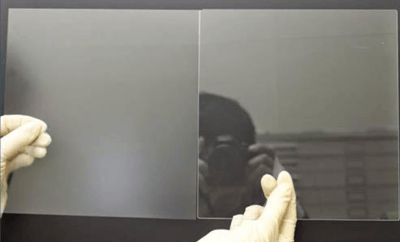

Anti-Glare Vs. Untreated

Anti-Reflective (AR) - Multiple layers with varying refractive indices vary the direction in which the light is reflected. Anti-reflective films are not visible to the human eye but can leave a soft blue-green color that may be subtly noticeable. Anti-reflective film is preferred in applications requiring high transitivity of light through the touch panel and when there is a higher intensity reflected light (e.g. outdoors).

Untreated Vs. Anti-Reflective

Anti-Fingerprint (AF) - It probably comes as no surprise that these touch panels are intended to be touched by people. Some amount of oil and residue are left behind when a panel is touched by someone’s finger, so AF surface treatments are made to resist these oils and dirt, as well as making the touchpanel easier to clean.

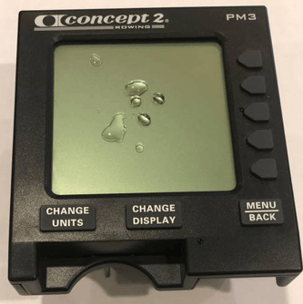

Wet Functional - Depending on the application, it’s possible for moisture to build up on the surface of the touch panel or for the end user to touch the display with wet hands. When this occurs, the accuracy of the touch panel response can be impacted. For these purposes, there are specific touch panel controllers and algorithms that better handle this interference and still retain a useful touch function.

Gloved Use - Capacitive touch panels are based on measuring the capacitance at each electrode in the touch panel. A finger or a stylus will change the electromagnetic field and alter the capacitance, which is then measured and converted into a location. Gloves can act as an insulator and block the electrical effect on the capacitance. This design process starts with knowing what type of gloves the end user will have and then designing the capacitive touch panel accordingly.

There are several possible adjustments that can be made if needed:

- Increase the strength of the capacitive field by increasing the distance between the driving electrode plane and the sensing electrode plane of the touch panel. In doing so, you effectively move the field beyond the surface of the touch panel. This has to be done carefully, as too much of an increase will get you false touches.

- Increase the power of the driving electrode. This is a touch panel controller specific, so not all of them have this adjustment capability.

- Minimize the distance between the user and the sensor. This is accomplished by using a thinner touch panel coverglass.

So, there’s an overview of capacitive panels and terms you should know. To further help you navigate this process, the following is a look at some of the most common questions - and our answers.

Question: Can you make these same surface treatments on resistive touch panels?

Answer: No, you cannot create or add surface treatments. Due to the flexible nature of the top substrate on a resistive touch panel, it has to be applied to a hard glass surface like a capacitive touch panel or overlay glass.

Question: Will this reduce the brightness of the overall LCD module?

Answer: Yes, depending on the treatment and the level of the treatment, it will reduce the brightness by 5-10%.

Question: Will this add cost to the display?

Answer: Yes, all treatments are additional processes and material, so they will add cost. AR is the most expensive, followed by AG and then AF.

Question: I don’t have a touch panel; can I still get these surface treatments?

Answer: Some LCD polarizers come in glossy or AG options, so an LCD display without a touch panel can indeed be made with an AG top surface.

We hope this information helps you begin your journey with capacitive panels. Please contact us any time if you have further questions, or to get started with your design.