The consumer television sector designed thinner displays and broader viewing angles to differentiate products and improve user experiences. These viewing angle improvements are now being adopted for the small-format industrial markets as well. What else can industrial display applications adopt?

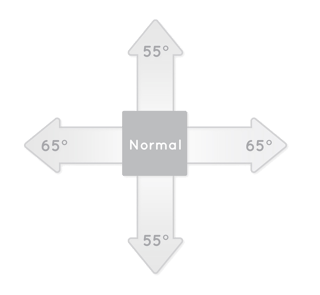

Let’s start with the simple TN TFT cell structure, 45-65 degree viewing angles as illustrated below:

Figure 1.Viewing Angle for Normal TFT

By adding extra wide polarizer film (EWP) to the traditional TN cell, the viewing angle may be increased about 10-15 degrees in each direction. But this will result in one or two directions being much narrower than the other three.

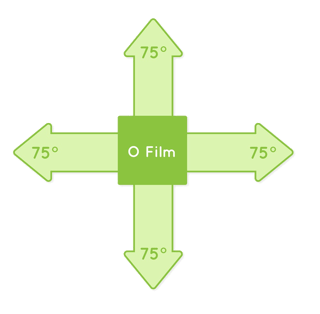

Another option is O-film enhancement polarizer film. This evenly widens the viewing angle to 75 degrees in each direction.

Figure 2. Viewing Angle for TFT with O-Film

Finally an advanced cell structure applying In-Plane switching (IPS) or Multi-Domain Vertical Alignment (MVA) cells can improve viewing angle approximately 85 degrees in each direction.

Quantum dot, another television-based innovation, can also be implemented. Quantum dot improves the color range of the cell. This is separate from viewing angle problems per se but it does relate to enhancing the overall viewing experience.

Customer Concerns & Options

It’s important to understand that consumer display product life cycles are far too short for industrial applications to take advantage of. Consumer products are designed for 1-2 years, where industrial applications may last in production for over a decade. This is important as many TFT platforms are designed for consumer applications and run the high risk of becoming obsolete early in the production phase of an industry type product.

Design concerns:

- - IPS and MVA type TFT cells are typically designed for the consumer market and have a higher risk of obsolescence.

- - Longer Lead times and higher minimum order quantities (MOQ’s). IPS and MVA are less common and can see six-month lead-times at times of lower global demand and far higher MOQ’s.

- - Cost. Due to complexity and availability MVA and IPS are more expensive than TN or TN with O-film.

- - Form factor availability. TN is much more common than IPS and MVA so there are many sizes and resolutions available in which O-film can be added.

Because the industrial customer typically wants a 10-year production life and IPS and MVA cells typically become obsolete within a few years, a much more practical viewing angle improvement is adding an enhancement film to a more readily available TN cell structure.

Key Applications

Products have emerged requiring improved viewing angle performance, particularly eliminating reduced contrast and color shift, at increasing angles. These include consumer televisions, automotive and industrial applications where the LCD display location is fixed but the end user/viewer will be in various positions. Monitoring equipment, safety equipment, fixed AV systems, rack mount systems, test equipment, medical and automotive are all current application areas where these challenges come into play.

With the advent of the O-film, improving the viewing angle is now typically a choice between O-film on a TN display or a higher-end cell structure such as IPS and MVA. And that decision is based on either product availability and/or cost performance trade off.

Figure 3. O-film Polarizer Viewing Angle Comparison

5.7E-O-Film.jpg?width=400&name=(01)5.7E-O-Film.jpg)

Conclusion

If the end product application requires a wider viewing angle there are several options. Choices are based on cost performance trade offs or and/or product availability. For example, if your design requires a wide viewing angle 2.4” QVGA TFT and it is only available in TN, the only option is O-film. If this same display is also available in IPS, you have the cost/ performance trade off to consider as well as the shortened product life cycle and potential longer lead times of the IPC cell over the TN+O-film solution.

To find out how we could directly help with your particular organization or issue, please contact us.